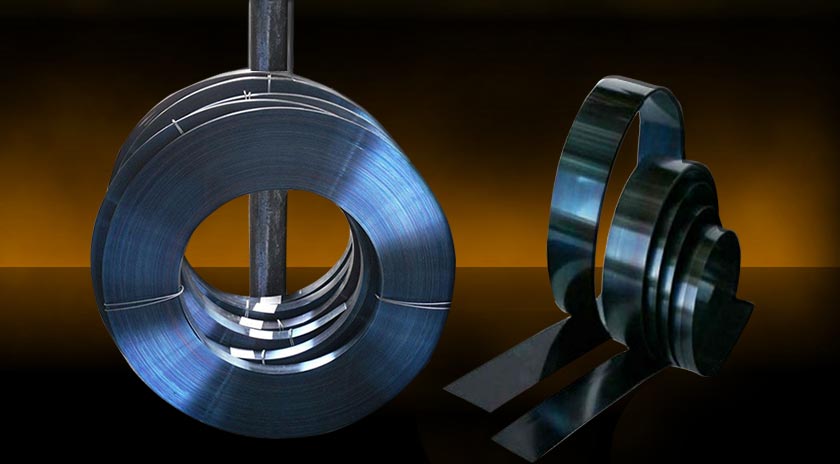

HARDENED & TEMPERED STEEL STRIPS C80

This Steel Strips Are

Popularly Known As

Hardened And Tempered Spring Steel Strips,

Spring Steel

Strips, Hardened Steel Strips,

Blue Tempered

Strips, Spring Strips.

This is high carbon steel strips with Martensite grain structure with high tensile strength, Produced by passing strips through long continuous heating furnace and oil quenching. Parts made from this strips have uniformity in hardness, flatness and shape as compared to parts made from annealed strips and then hardened in batches.

These strips are usually available in C80 grade per the standard sizes available in stock but also can be provided in C75 & C98 grades if quantities required are viable to produce. These strips are supplied with various option as per requirement of customer. Edges Slit, rounded or dressed. Surface finish Bright polished, grey (un polished), polished and blued or golden.

Hardened & Tempered Steel Strips Specification & Application

Properties

- Edges Sheared

- Finish Grey, bright polished, or blue

- Flatness 0.025mm Max per 25mm of width.

| GRADE | CARBON | MANGANESE | SILICON | SULPHUR | PHOSPHORUS |

|---|---|---|---|---|---|

| C-80 | 0.75-0.85% | 0.6-0.90% | 0.0-0.35% | 0.35%MAX | 0.35%MAX |

| C-62/C-65 | 0.60-0.69% | 0.6-0.90% | 0.35% MAX | 0.35%MAX | 0.35%MAX |

| C-75 | 0.70-0.80% | 0.60-0.90% | 0.35% MAX | 0.35%MAX | 0.35%MAX |

| C-98 | 0.95-1.5% | 0.35-0.80% | 0.15-0.35% | 0.35%MAX | 0.35%MAX |

THIS STRIPS ARE WIDELY USED IN THIS APPLICATIONS

- Power springs

- Flat springs

- Coil springs

- Wood cutting band saw blades

- Handsaw blades

- Masonry tools

- Gardening tools

- CLOCK SPRINGS

- Doctor blades

- Cutting blades

- Washers

- Wave washers

- Spring components with less bending

- Rolling shutter springs for doors and windows

- Loom drop pins

- Textile heald frames

- Horn diaphragm

- Clutch parts

- Door closure springs

- Valve plates

- Compressor parts

- Shock absorber washers

Standard sizes of hardened and tempered strips in stock

| Grade | Thickness | Width | Length | Hardness | Surface | Finish |

|---|---|---|---|---|---|---|

| C80 | 3.0MM | 300MM | 2050MM | 44-47 | HRC | Bright |

| C80 | 2.50MM | 300MM | 3050 | 44-47 | HRC | Bright |

| C80 | 2.0MM | 200MM | Coils | 44-47 | HRC | Bright |

| C80 | 2.0MM | 154.2MM | Coils | 44-47 | HRC | Bright |

| C80 | 1.80MM | 154.2MM | Coils | 44-47 | HRC | Bright |

| C80 | 1.60MM | 154.2MM | Coils | 44-47 | HRC | Bright |

| C80 | 1.50MM | 154.2MM | Coils | 44-47 | HRC | Bright |

| C80 | 1.40MM | 154.2MM | Coils | 44-47 | HRC | Bright |

| C80 | 1.40MM | 127MM | Coils | 44-47 | HRC | Bright |

| C80 | 1.20MM | 154.2MM | Coils | 44-47 | HRC | Bright |

| C80 | 1.20MM | 127MM | Coils | 44-47 | HRC | Bright |

| C80 | 1.20MM | 100MM | Coils | 44-47 | HRC | Bright |

| C80 | 1.0MM | 200MM | Coils | 44-47 | HRC | Bright |

| C80 | 1.0MM | 150MM | Coils | 44-47 | HRC | Bright |

| C80 | 0.90MM | 200MM | Coils | 44-47 | HRC | Bright |

| C80 | 0.80MM | 200MM | Coils | 44-47 | HRC | Bright |

| C80 | 0.80MM | 152.4MM | Coils | 44-47 | HRC | Bright |

| C80 | 0.70MM | 150MM | Coils | 44-47 | HRC | Bright |

| C80 | 0.60MM | 165MM | Coils | 44-47 | HRC | Bright |

| C80 | 0.50MM | 200MM | Coils | 44-47 | HRC | Bright |

| C80 | 0.50MM | 150MM | Coils | 49-51 | HRC | Bright |

| C80 | 0.50MM | 150MM | Coils | 49-51 | HRC | Blue |

| C80 | 0.40MM | 150MM | Coils | 49-51 | HRC | Bright |

| C80 | 0.40MM | 150MM | Coils | 49-51 | HRC | Blue |

| C80 | 0.30MM | 150MM | Coils | 49-51 | HRC | Bright |

| C80 | 0.30MM | 150MM | Coils | 49-51 | HRC | Blue |

| C80 | 0.25MM | 150MM | Coils | 49-51 | HRC | Bright |

| C80 | 0.25MM | 150MM | Coils | 49-51 | HRC | Blue |

| C80 | 0.20MM | 150MM | Coils | 49-51 | HRC | Bright |

| C80 | 0.20MM | 150MM | Coils | 49-51 | HRC | Blue |

| C98 | 0.18MM | 200MM | Coils | 53-57 | HRC | Bright |

| C98 | 0.15MM | 150MM | Coils | 53-57 | HRC | Bright |

| C98 | 0.12MM | 150MM | Coils | 53-57 | HRC | Bright |

| C98 | 0.10MM | 150MM | Coils | 53-57 | HRC | Bright |

| C98 | 0.075MM | 100MM | Coils | 53-57 | HRC | Bright |

| C98 | 0.05MM | 100MM | Coils | 53-57 | HRC | Bright |