C80 Annealed Steel Strips

This Grade Of

Steel Is popularly known as

Spring Steel

Strip Annealed, Spring Steel Strip Unhardened, High

Carbon Steel Strip,

Cold Rolled Steel Strip.

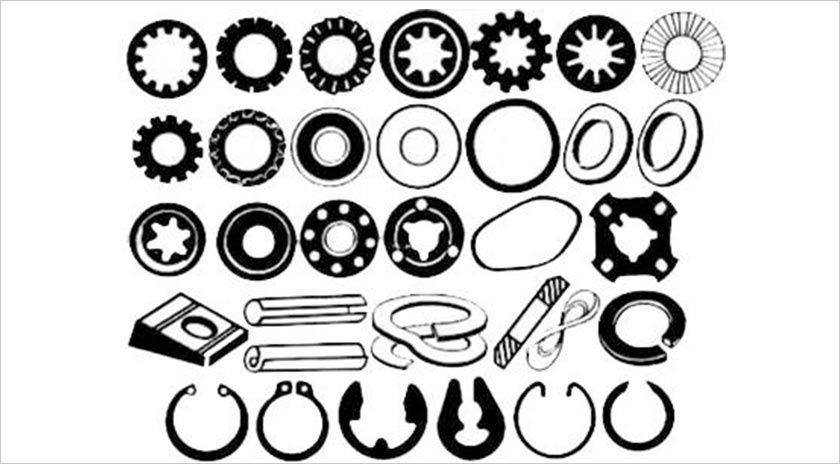

This is a High Carbon cold rolled steel strip, with Spherodized grain structure, this steel is with a very high yield strength. This allows objects made of this steel to return to their original shape despite significant bending or twisting after hardening and tempering.

Usually in soft annealed condition but can also be supplied in temper rolled hardness in range between 200-350 Hv (band range is+/- 40 Hv) These grade of steel is used where fatigue value and elastic limits are critical it is also used where high strength, hardness and wear resistant is needed. These steel has good forming and blanking properties but very poor drawing property.

Properties of C80 grade cold rolled annealed steel strips

Properties of C80 grade cold rolled annealed steel

strips

Chemical composition by weight

Physical properties

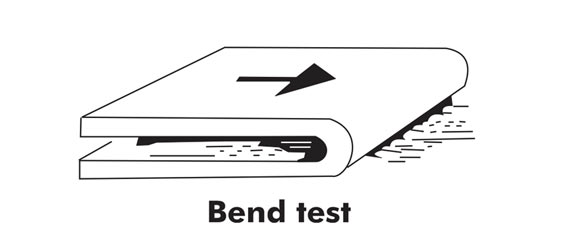

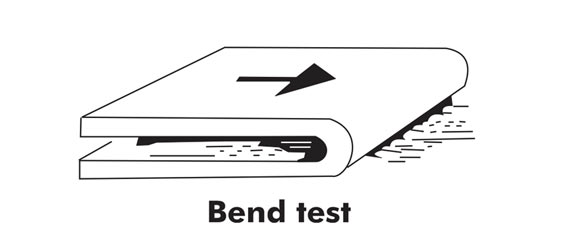

• Bend test When bending maintain radius as follows :

'r' stands for radius of bend and 't' for thickness of strip.

Other Properties

| Carbon | 0.75 - 0.85% | |||

| Manganese | 0.60 - 0.90% | |||

| Silicon | 0.0-0.35% | |||

| Sulphur | 0.025% | |||

| Phosphorous | 0.025% | |||

| This grade is similar to 80c6 of IS2507 of 1975 & C1080 |

- Hardness is annealed condition 200Hv Max

- Yield strength 290 N/MM2

- Elongation 25% Minimum

- Tensile strength 640N/mm2

- Surface bright and free from any detrimental surface defect

- Edges Clean slit

• Bend test When bending maintain radius as follows :

| Grain Wise | Against Grains | ||||

|---|---|---|---|---|---|

| For thickness 4.00 mm to 2.50 mm | r=2t | not advised | |||

| For thickness 2.30 mm to 1.20 mm | r=1t | not advised | |||

| For thickness 1.0 mm to 0.50 mm | r=0t | r=1t | |||

| For thickness 0.45 mm to 0.20 mm | r=0t | r=0r |

Form of Supply

- Usually in coils, thicker strips can also be supplied in cut to length and levelled strips

- Edges are slitted

- Coil ID 300-500mm as per mutual agreement with buyer

- Coil weight as per mutual understanding with buyer

- Surface finish is

bright suitable for electroplating

Width: Usually is between 300-450mm, however we can slit as per customers requirement.

Thickness: 45mm to 0.20mm range as per following divisions and thickness tolerance.

we accept orders for other specific thickness. However the order quantity and lead time for supply is to be confirmed by us.

PS: Sizes mentioned are for reference only and may change following trends.

Thickness: 45mm to 0.20mm range as per following divisions and thickness tolerance.

- 4.50mm + 0.07mm

- 3.50mm + 0.05mm

- 3.20mm + 0.05mm

- 2.80mm + 0.05mm

- 2.60mm + 0.04mm

- 2.50mm + 0.04mm

- 2.30mm + 0.04mm

- 2.00mm + 0.04mm

- 1.80mm + 0.04mm

- 1.75mm + 0.04mm

- 1.50mm + 0.03mm

- 1.48mm + 0.03mm

- 1.20mm + 0.03mm

- 1.0mm + 0.03mm

- 0.98mm + 0.03mm

- 0.90mm + 0.03mm

- 0.80mm + 0.03mm

- 0.70mm + 0.03mm

- 0.60mm + 0.03mm

- 0.55mm + 0.02mm

- 0.50mm + 0.02mm

- 0.45mm + 0.02mm

- 0.40mm + 0.02mm

- 0.30mm + 0.02mm

- 0.25mm + 0.02mm

- 0.20mm + 0.02mm

we accept orders for other specific thickness. However the order quantity and lead time for supply is to be confirmed by us.

PS: Sizes mentioned are for reference only and may change following trends.